There are several types of furnaces commonly used in research work, each with its own benefits and limitations. Here are some of the most common types:

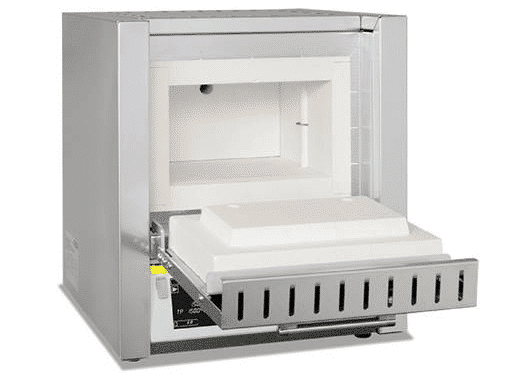

Muffle furnace:

A muffle furnace is designed to heat materials to high temperatures within a controlled environment. Typically constructed from heat-resistant materials like ceramic or brick, the furnace features a sealed chamber called a muffle where the material is placed. Key advantages of a muffle furnace include precise temperature control, high heating rates, and excellent thermal insulation. However, its limitations include a restricted maximum temperature range, generally reaching up to about 1200°C.

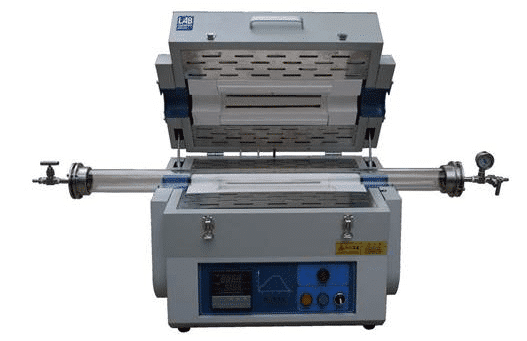

Tube furnace:

A tube furnace heats materials inside a long, cylindrical chamber, usually made from heat-resistant materials like ceramic or metal. The material is placed in a quartz or alumina tube within the furnace. Tube furnaces can achieve a wide range of temperatures, often up to around 1700°C, and offer good temperature uniformity. The main limitations are the restricted space for larger samples and a longer heating duration.

Box furnace:

A box furnace heats materials in a rectangular chamber, typically constructed from heat-resistant materials such as ceramic or metal. Materials are placed on a tray inside the furnace. Box furnaces can reach temperatures up to approximately 1800°C and offer a large chamber for accommodating bigger samples. However, they often have poorer temperature uniformity and slower heating rates compared to other furnace types.

Induction furnace

Induction furnaces are highly efficient electric furnaces that utilize induction heating to melt metals, commonly used in foundries for melting and pouring metals such as steel, iron, aluminum, and copper. Research areas include enhancing the efficiency of the heating process, optimizing melting processes for specific metals or alloys, and developing new materials for furnace components to extend their lifespan. Advantages of induction furnaces include faster melting times, higher efficiency, reduced pollution, and the capability to melt a wide range of metals and alloys. They can melt metals at temperatures up to 3000°C, produce high-quality castings with excellent metallurgical properties, and are suitable for controlled heating, annealing, surface hardening, and heat treatment processes.

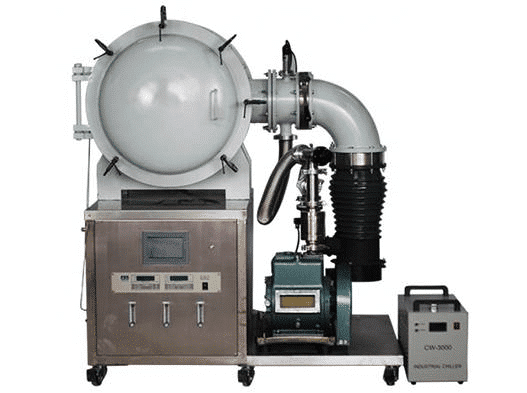

Vacuum Furnace

A vacuum furnace operates in a low-pressure or vacuum environment, preventing the oxidation and contamination of processed materials. Widely used in industries such as aerospace, automotive, electronics, and medical devices, vacuum furnaces process materials like metals, ceramics, and composites. Capabilities include:

- Controlled Atmosphere Processing: Minimizes oxidation and contamination, crucial for sensitive materials like titanium and certain alloys.

- High-Temperature Processing: Suitable for heat treating, sintering, and other high-temperature processes, with some models reaching up to 3000 °C.

- Precise Temperature Control: Achieved using heating elements, thermocouples, and advanced control systems, essential for many applications.

- Uniform Heating: ensures even heating of materials, which is critical for producing high-quality materials meeting specific standards.

- Batch and Continuous Processing: Available in configurations for both small production runs (batch processing) and large-scale production (continuous processing).

Conclusion

The selection of a furnace depends on the specific research requirements, including the type of material, desired temperature range, heating rate, and temperature uniformity.