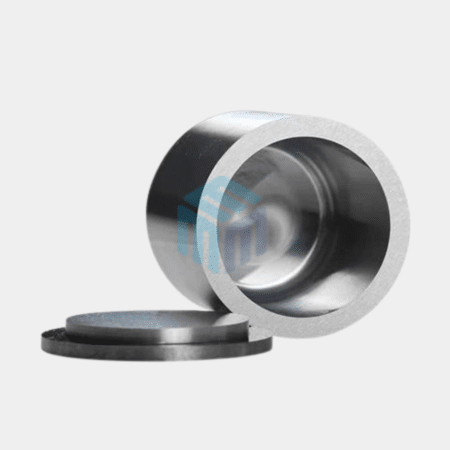

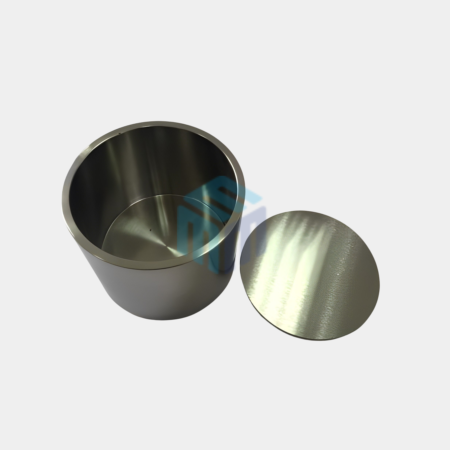

Tungsten Carbide Rods/ Tubes

Inquiry NowProduct Description

Tungsten carbide tubes and rods are specialized materials commonly used in various industrial applications due to their exceptional hardness, wear resistance, and high-temperature performance. They are made from tungsten carbide (WC), a compound of tungsten and carbon, and are used in a wide range of industries for their unique properties. Here are some key features and applications of tungsten carbide tubes and rods:

Key Features:

- Exceptional Hardness: Tungsten carbide is one of the hardest materials known, making tubes and rods highly resistant to wear and abrasion.

- High-Temperature Resistance: Tungsten carbide can withstand extreme temperatures, which makes it suitable for applications involving high heat and thermal stress.

- Chemical Inertness: Tungsten carbide is chemically inert and resistant to most corrosive chemicals, enhancing its durability in harsh environments.

- Excellent Mechanical Strength: Tungsten carbide tubes and rods have impressive mechanical strength and can withstand high pressures and loads.

- Electrical Conductivity: Tungsten carbide has good electrical conductivity, allowing its use in electrical and electronic applications.

Applications:

- Machining and Cutting Tools: Tungsten carbide rods are commonly used as tool blanks for cutting, drilling, and machining applications. They provide high wear resistance and can maintain sharp cutting edges for extended periods.

- Wear Parts: Tungsten carbide rods and tubes are used in the manufacture of wear-resistant components, such as nozzles, valves, and pump parts, for applications in industries like mining and oil and gas.

- Tooling and Forming Dies: Tungsten carbide rods and tubes are utilized for making tooling and forming dies used in metal stamping, forging, and extrusion processes.

- Rotary Burrs: Tungsten carbide rods are used to create rotary burrs for shaping, deburring, and grinding applications, especially in metalworking and machining.

- Wire Drawing: Tungsten carbide tubes are employed in wire drawing dies used to reduce the diameter of wires, cables, and tubes in industries like wire manufacturing.

- High-Pressure Applications: Tungsten carbide tubes can withstand high-pressure and high-temperature conditions, making them suitable for use in oil and gas drilling tools and high-pressure chambers.

- Electrodes: Tungsten carbide rods can be used as electrodes for electrical discharge machining (EDM) and in spark erosion processes.

- Welding Electrodes: Tungsten carbide rods are used in welding applications to create hardfacing or build-up materials for wear-resistant surfaces on equipment and machinery.

- Surgical and Medical Instruments: Tungsten carbide rods and tubes are used to manufacture precision surgical instruments, such as dental drills and bone saws, due to their sharpness and biocompatibility.

- Electronics: Tungsten carbide rods can be used as electrical contacts and conductive components in electronic devices and equipment.

Tungsten carbide tubes and rods are available in various dimensions, shapes, and compositions to suit specific applications. They are often customized to meet the unique requirements of each industry. Proper selection and handling are crucial to ensure their optimal performance and longevity in various applications.

We are an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.