Tungsten Carbide Grinding Media

Inquiry NowProduct Description

Tungsten carbide grinding media, often referred to as tungsten carbide beads or balls, are high-density and ultra-hard grinding media primarily composed of tungsten carbide (WC) particles. They are used in various industrial applications for grinding, milling, and dispersing materials. Tungsten carbide grinding media are known for their exceptional hardness, wear resistance, and high-temperature performance. Here are key features and applications of tungsten carbide grinding media:

Key Features:

- Extreme Hardness: Tungsten carbide grinding media are one of the hardest materials available and can efficiently grind or mill materials that are harder than themselves.

- Wear Resistance: They offer excellent wear resistance, leading to longer service life and minimal contamination of the materials being processed.

- Chemical Inertness: Tungsten carbide is chemically inert, making it compatible with a wide range of chemicals and solvents, suitable for various applications.

- High Thermal Stability: Tungsten carbide grinding media can withstand high temperatures, ensuring stability in high-temperature processing environments.

Applications:

- Ball Milling: Tungsten carbide grinding media are commonly used in ball mills and stirred mills for the purpose of grinding and dispersing materials. They find use in industries such as ceramics, mining, and materials science.

- Mining and Minerals Processing: In the mining industry, they are used in grinding mills for the comminution of ores and minerals, ensuring efficient particle size reduction.

- Ceramic Industry: Tungsten carbide grinding media are used for grinding ceramic raw materials, glazes, and pigments during the production of ceramic tiles, advanced ceramics, and refractory materials.

- Paints and Coatings: They are employed in the production of paints, inks, and coatings for dispersion and milling processes, ensuring fine particle size and uniform distribution of pigments.

- Chemical Processing: Tungsten carbide grinding media find applications in chemical reactors and vessels for processes involving corrosive chemicals and high temperatures.

- Metallurgy: They are used in various metallurgical processes, such as the grinding of ferrous and non-ferrous metals in mineral processing and ore beneficiation.

- Pharmaceuticals: In pharmaceutical manufacturing, tungsten carbide grinding media are used for grinding and processing active pharmaceutical ingredients (APIs), excipients, and drug formulations.

- Food Industry: They are employed in food processing for grinding and dispersing food ingredients, such as chocolate, confectionery, and pastes.

- Cosmetics: In the cosmetic industry, tungsten carbide grinding media are used for processing and milling cosmetic ingredients and formulations.

- Advanced Materials: In the production of advanced materials, such as composites, catalysts, and nanomaterials, tungsten carbide grinding media play a critical role in achieving the desired material properties.

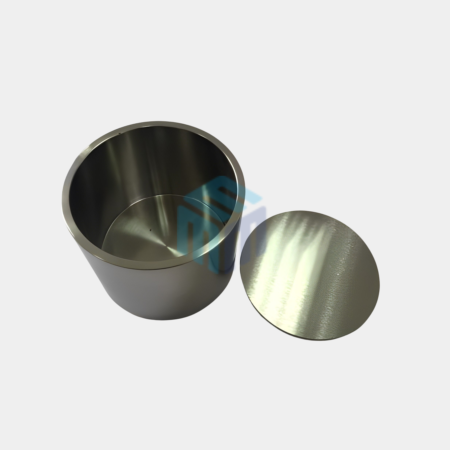

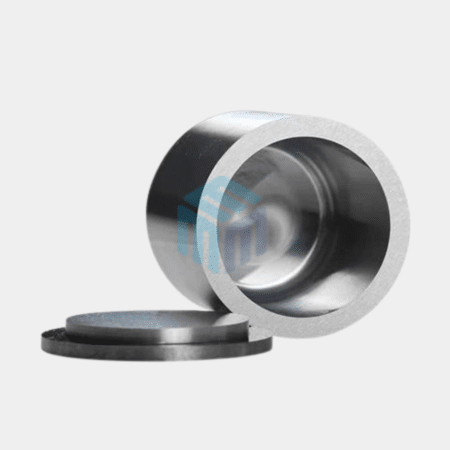

Tungsten carbide grinding media come in various sizes and shapes, and their selection depends on the specific requirements of the application, such as the particle size, material being processed, and the type of mill or equipment used. The choice of tungsten carbide grinding media can significantly impact the efficiency and quality of the grinding or milling process.

We are an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.