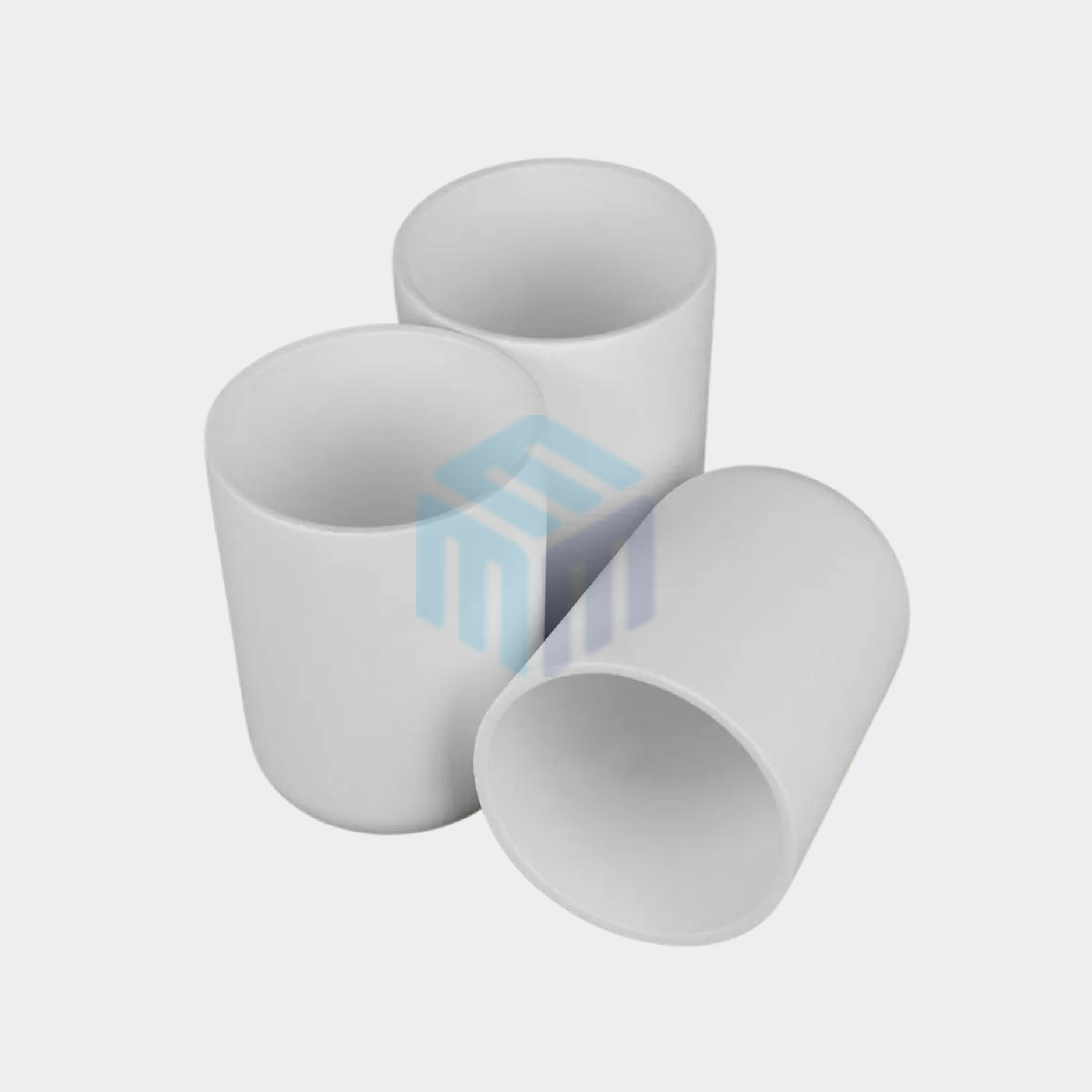

Zirconia Crucibles

Inquiry NowProduct Description

Zirconia crucibles are specialized containers or vessels made from zirconium dioxide (ZrO2) or stabilized zirconia materials. They are commonly used in high-temperature and extreme environments, especially in laboratories, research, and industrial processes.

Zirconia crucibles Dimensions & Customization

Zirconia crucibles come in various shapes and sizes to suit different applications, and they can be customized to meet specific requirements, such as crucible dimensions, lids, and coatings. When selecting a zirconia crucible for a particular application, it’s important to consider factors like the required temperature range, chemical compatibility, and the volume of material to be processed. Additionally, proper handling and care should be taken to avoid thermal shock and maintain the crucible’s integrity.

Properties of Zirconia crucibles

Zirconia crucibles have several unique properties that make them suitable for specific applications:

- High-Temperature Resistance: Zirconia crucibles can withstand very high temperatures, making them suitable for applications involving the melting, sintering, or heat treatment of various materials.

- Chemical Inertness: Zirconia is chemically inert, which means it does not react with most chemicals and substances, making it suitable for use with reactive materials.

- Excellent Thermal Shock Resistance: Zirconia crucibles have good thermal shock resistance, allowing them to withstand rapid temperature changes without cracking or breaking.

- Low Thermal Conductivity: Zirconia has low thermal conductivity, which is important in applications where controlled heating or cooling rates are necessary.

- Electrically Insulating: Zirconia is an electrical insulator, which is essential for certain high-temperature electrical applications.

Various Applications of Zirconia Crucibles

- Metallurgy: Zirconia crucibles are used in the melting and casting of metals, especially those with high melting points. They are employed in the production of superalloys, steel, and other advanced materials.

- Ceramic and Glass Processing: Zirconia crucibles are used in the production of ceramics and glass, including the melting and crystallization of glass materials.

- Laboratory and Research: Zirconia crucibles are used in laboratories for high-temperature sample preparation, thermal analysis, and material research.

- Chemical Processing: Zirconia crucibles are used for chemical reactions and the testing of materials that require resistance to corrosive chemicals.

- Precious Metal Analysis: They are used in the analysis of precious metals, such as gold and platinum, due to their high-temperature stability.

- Sintering and Annealing: Zirconia crucibles are used for sintering and annealing processes, such as the densification of ceramics.

- Pharmaceuticals and Biotechnology: Zirconia crucibles can be used for high-temperature processes in pharmaceutical and biotechnology applications.

- Environmental Testing: They are used for high-temperature environmental testing and analytical applications.

Work with Trusted Zirconia Crucibles Suppliers Across India

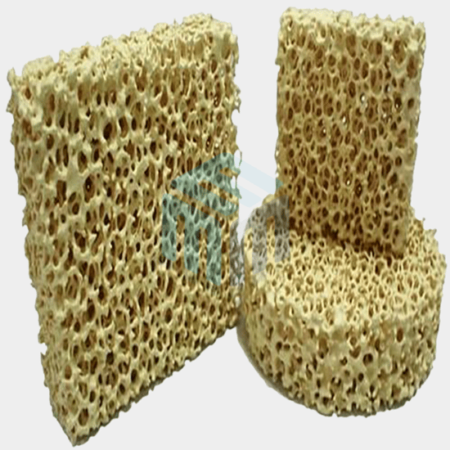

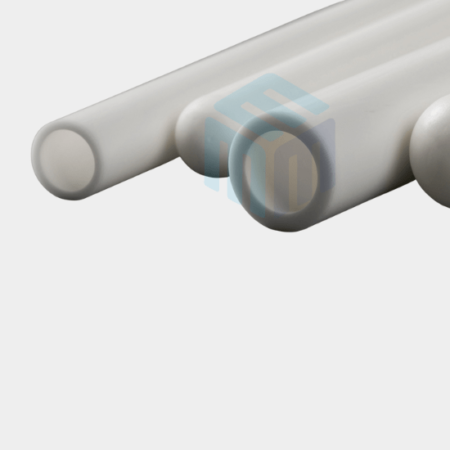

M-Kube Enterprise proudly serves customers across the India and around the globe—including Australia, New Zealand, India, Singapore, Malaysia, South Korea, Indonesia, the Philippines, Dubai, and Vietnam. We are trusted suppliers of zirconia crucibles, Zirconia Tubes & Rods, Foam Filters. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.

Frequently Asked Questions:

What is a zirconia crucible?

A zirconia crucible is a container made from zirconium dioxide (ZrO₂), known for its high melting point (≈ 2,700°C), thermal shock resistance, and chemical inertness. It’s commonly used to melt or process metals, ceramics, and glass under extreme heat. As reliable zirconia crucibles suppliers, we offer high-performance crucibles suitable for demanding thermal and chemical environments across various industries.

What are the main benefits of zirconia crucibles?

- Ultra-high temperature resistance

- Excellent corrosion and chemical resistance

- Low thermal conductivity

- Stable in both oxidizing and reducing environments

- High purity (often >99.5%)

What industries use zirconia crucibles?

- Metallurgy

- Aerospace

- Research laboratories

- Ceramics & glass processing

- Semiconductor & electronics

What are alternatives to zirconia crucibles?

Depending on the application, alternatives include:

- Alumina crucibles (lower cost, moderate temp range and lower thermal shock resistance)

- Magnesia crucibles (higher cost, higher temp range and lower thermal shock resistance)

- Graphite crucibles (higher temp range, excellent thermal shock resistance, but for reducing atmospheres)

- Quartz crucibles (lower cost, lower temp range and higher thermal shock resistance)

Are zirconia crucibles expensive?

Yes, due to the high cost of raw zirconia and specialized manufacturing. However, they often last longer than cheaper alternatives under extreme conditions, offering better long-term value.