Tungsten Crucibles

Inquiry NowProduct Description

General information

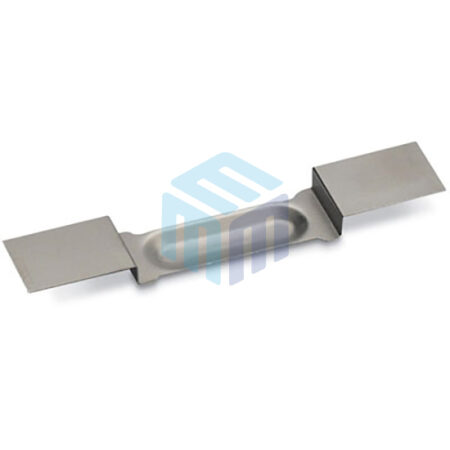

Tungsten crucibles are manufactured by three significant processes – sintering, stamping or spinning. Each process has produced crucibles that are apt for a variety of specific uses. Crucibles are made up of pure tungsten plates, rods and sheets.

Tungsten crucibles need to be manufactured with caution to avoid losing its quality and properties such as resistance to corrosion and abrasion, high melting and boiling point, good strength, high thermal conductivity. It displays brilliant high temperature strength, hardenability along with low thermal expansion coefficient.

We are an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.

We also provide Tungsten Wires, Tungsten Boats, Tungsten Electrodes, Tungsten Mandrels, Tungsten Foils, Tungsten Sheets and Plates, Tungsten Tubes, Tungsten Rods and Bars, and Tungsten substrates.

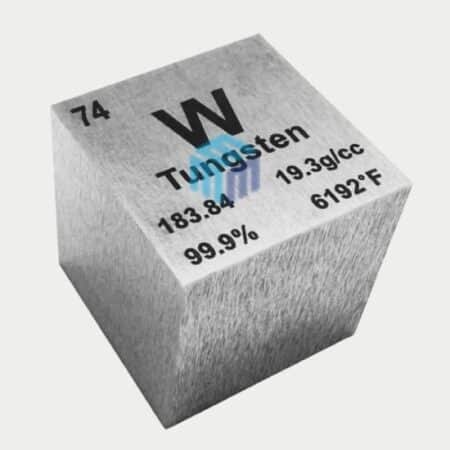

Key properties

- High melting point (3410 °C)

- Low thermal expansion

- High electrical resistance

- Low vapour pressure

- High density

- Resistance to oxidation and creep

- Extreme hardness

- High tensile strength

Application

Tungsten crucibles, that is has high boiling and melting point and is resistant to corrosion and abrasions, are used: –

- As vessels in industrial furnaces

- For sapphire crystal growth furnaces

- For quartz glass industries

- For rare earth smelting

Product FAQ's

Tungsten crucibles are available in a variety of standard and custom shapes, including:

Cylindrical crucibles

Conical crucibles

Flat-bottomed or round-bottomed designs

Open-top or versions with fitted lids (Lids with steps ensure a secure and tight fit)

Dimensions can vary significantly depending on your specific industrial or laboratory application, with custom options available upon request.

Yes, custom fabrication is widely available. Suppliers typically offer flexibility in:

Diameter, height, and wall thickness

Shapes such as cylindrical, conical, boat-shaped, or square

Surface finish, including polished, rough, or machined

Tolerance and precision levels

Material purity, often 99.95% or 99.99%

Open or closed-end designs with optional step-fitted lids

Custom drawings or technical specifications from clients

To ensure accurate manufacturing, provide:

Intended use or application

Complete dimensions (inner/outer diameter, height, wall thickness)

Desired material purity (commonly 99.95% or higher)

Required quantity and expected delivery timeline

Any technical drawings or special design features

Consider suppliers who offer:

Material certification, especially purity levels of ≥99.95%

Expertise in custom manufacturing and advanced machining

Clear pricing structures and international shipping options

Responsive customer support and technical consultation

Positive client reviews or references in your industry

Store in a clean, dry, and stable environment

Handle with gloves or tools to avoid contamination

Avoid exposure to moisture or corrosive substances

Prevent mechanical impacts that could cause microcracks or deformation

Yes, most reputable suppliers offer worldwide shipping. Delivery costs will depend on:

Product weight and size

Destination country

Applicable customs duties or import taxes

Let me know if you’d like this version styled for a website, PDF catalog, or email inquiry format.