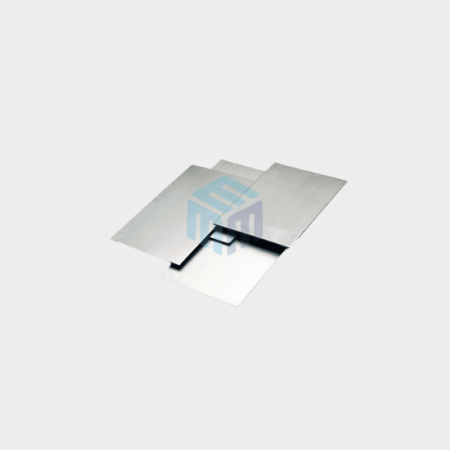

Molybdenum Foil

Inquiry NowProduct Description

General Information

Molybdenum foils are generally made from molybdenum plate. Molybdenum is rolled into foils that are 0.2mm in size, retaining 99.9% purity. Molybdenum foils are advantageous because of their mechanical properties such as bending, spinning, drawing, stamping, which can be used in high temperatures.

Molybdenum foils have even metallic surfaces. Molybdenum foils are light and pliable, therefore apt for space purposes. Its high resistance to high temperatures makes it an apt material to use as a shield from heat and x-rays.

We are an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.

We also provide Molybdenum Wires, Molybdenum Electrodes, Molybdenum Mandrels, Molybdenum Crucibles, Molybdenum Sheets and Plates, Molybdenum Tubes, Molybdenum Rods, and Molybdenum substrates

Key Features

Molybdenum is a refractory material that can withstand high temperatures, even higher than steel and nickel alloys. Due to its oxidation at low temperatures, it is best to use Molybdenum Crucibles in vacuum. Significant features include –

- High purity

- High creep resistance

- High dimensional stability

- Low co-efficient of thermal expansion

- Good thermal conductivity

- Good electrical conductivity

- Good stiffness, greater than that of steel

- High melting point (2622 °C)

- High boiling point (4639 °C)

- High red-hardness

- Good strength and ductility

- High density

Applications

Due to molybdenum foil’s mechanical and physical properties, it is used: –

- For manufacturing electric light source parts

- For producing components of electric vacuum

- For producing electric power semiconductor

- For manufacturing molybdenum boats,

- As shield in high temperature furnace

- To make sputtering targets (Molybdenum layers are essential for thin-film transistors used in TFT-LCD and OLED screens. They aid in regulating each pixel at lightning speed, ensuring clear images. Other purposes of Molybdenum layers include as parts of microelectronics and back contact in solar cells).

Molybdenum Foil are often used in the following industries and applications:

- Aerospace

- Metal Industry

- Metallurgy

- Stainless steel and Steel Industry

- Solar Cell

- Fuel Cell

- Energy Storage

- Nanotechnologies

- Electronic

- Chemical Vapor Deposition Research

- Atomic Layer Deposition research