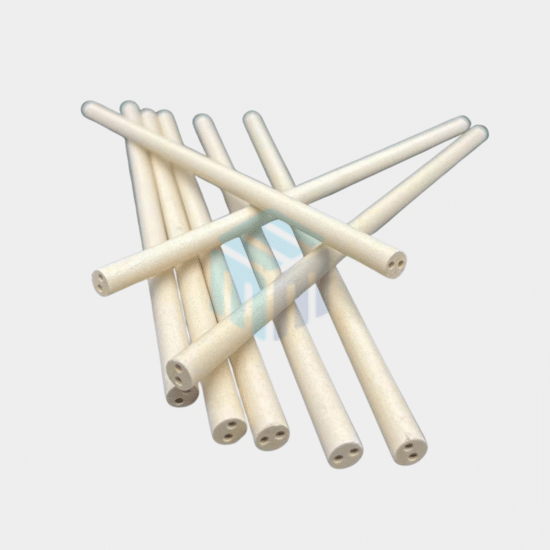

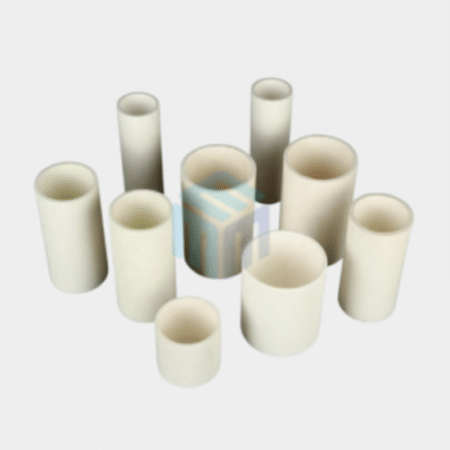

Magnesia Tubes And Rods

Inquiry NowProduct Description

Magnesia tubes and rods are specialized materials made from magnesia or magnesium oxide (MgO). They are used in a variety of high-temperature and chemically aggressive environments due to their excellent thermal and chemical resistance. Magnesia is a refractory material that can withstand extreme conditions, making magnesia tubes and rods suitable for several industrial applications. Here are some key features and applications of magnesia tubes and rods:

Key Features:

- High-Temperature Resistance: Magnesia has excellent refractory properties and can withstand extremely high temperatures, making it ideal for use in furnaces, kilns, and other high-temperature processes.

- Chemical Inertness: Magnesia is chemically inert and resistant to most chemical reactions, making it suitable for applications where corrosion resistance is required.

- Thermal Insulation: Magnesia is a good thermal insulator, making it valuable for applications where thermal management is necessary.

- Electrical Insulation: Magnesia is electrically insulating, making it suitable for electrical applications where insulation is essential.

Applications:

- Heating Elements and Furnace Components: Magnesia rods are used in electric heating elements and as components in high-temperature furnaces and kilns, as they can withstand the extreme temperatures and provide electrical insulation.

- Thermocouple Protection Tubes: Magnesia tubes are used to protect thermocouples from harsh environments, such as those found in steel and glass manufacturing, where high temperatures and chemical reactions can occur.

- Analytical Instruments: Magnesia tubes and rods are used in various analytical instruments and lab equipment, especially in applications where high temperatures and chemical resistance are required.

- Ceramic Kilns and Pottery: Magnesia is used to manufacture tubes and rods for use in ceramic kilns and pottery ovens, where it can withstand the high firing temperatures and provide thermal insulation.

- Chemical Processing: Magnesia tubes and rods are used in chemical reactors and vessels for processes involving corrosive chemicals and high temperatures.

- Glass Manufacturing: They are used in the glass industry for applications like glass melting furnaces and forehearths, where magnesia’s high-temperature resistance is essential.

- Metallurgy: Magnesia tubes and rods find application in various metallurgical processes, such as steelmaking and non-ferrous metal smelting, due to their ability to withstand high temperatures and chemical conditions.

- Foundry and Casting: They can be used in foundry and casting applications for the production of alloys and metals in high-temperature environments.

- Aerospace and Aviation: Magnesia is used in certain aerospace applications, where its high-temperature resistance and thermal insulating properties are valuable.

- Thermal Analysis: They are used in thermal analysis equipment and instruments for studying the thermal properties of materials.

Magnesia tubes and rods come in various sizes and shapes to meet the specific requirements of different industries and applications. They are often customized to withstand particular temperature ranges and chemical conditions. Proper selection and handling are crucial to ensure optimal performance and longevity in various applications.

We are an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.