Introduction

In modern high-temperature furnaces, precision, durability, and efficiency are crucial. That’s where Silicon Carbide (SiC) heating elements come into play. These advanced components are widely used in industries ranging from metallurgy and ceramics to glass, electronics, and lab-scale material processing. But how do they actually work, and what makes them ideal for extreme thermal applications?

This blog delves into the working principle of SiC heating elements, their structure, and tips to maximize their performance in high-temperature environments.

What Are Silicon Carbide Heating Elements?

Silicon carbide heating elements are rod- or tube-shaped components made primarily from high-purity SiC ceramic. They are designed to convert electrical energy into heat through resistive heating, reaching temperatures up to 1600°C (2912°F). These elements are commonly found in silicon carbide heating element furnaces, sintering equipment, kilns, and lab furnaces.

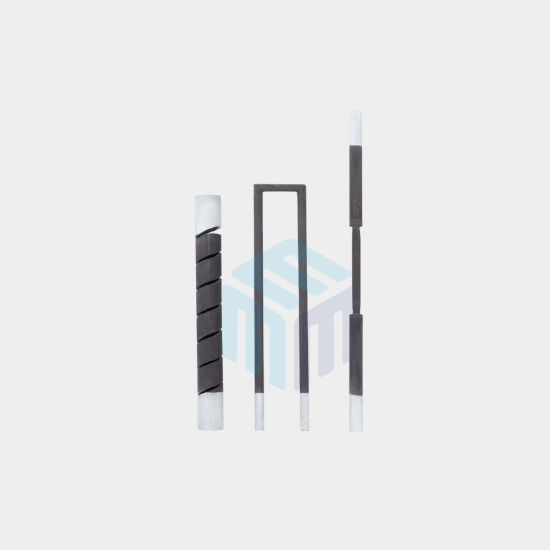

Typical forms include:

- Silicon carbide heating rods

- SiC heating tubes

- U-type or spiral-type SiC heaters

Thanks to their oxidation resistance, high thermal conductivity, and mechanical strength at elevated temperatures, SiC elements provide long service life and consistent performance under harsh conditions.

How Do Silicon Carbide Heating Elements Work?

SiC heating elements operate on the principle of Joule heating. When electric current passes through the silicon carbide material, electrical resistance generates heat.

Here’s a step-by-step overview of how they function in a furnace:

- Power Supply: The furnace’s electrical system sends a controlled current to the SiC heating element.

- Resistive Heating: The silicon carbide’s inherent resistance to electricity causes it to heat up.

- Radiant Heat Transfer: The element emits infrared radiation, transferring heat to the furnace chamber and the materials inside.

- Temperature Control: Advanced temperature controllers monitor and adjust the current to maintain uniform heat.

Over time, some electrical resistance drift can occur as the SiC material oxidizes. However, modern elements are designed to accommodate this, ensuring reliable performance over extended use.

Tips for Maximizing SiC Heating Element Performance

To extend the life and efficiency of your silicon carbide heater, consider the following best practices:

- Proper Installation: Align elements correctly and avoid mechanical stress to prevent breakage.

- Avoid Overheating: Operating above the rated temperature can cause premature degradation.

- Use Compatible Power Controllers: Phase-angle or zero-cross controllers are ideal to limit electrical surges.

- Maintain Furnace Atmosphere: SiC elements work best in air or inert gases. Avoid reducing atmospheres unless specially designed for it.

- Regular Inspections: Monitor resistance values and inspect for surface wear to identify aging early.

- Choose Quality SiC Crucibles: For optimal compatibility and thermal efficiency, pair your SiC heating system with SiC crucibles of matching quality.

Conclusion

Silicon carbide heating elements are an indispensable part of high-temperature furnace technology. Their excellent thermal performance, durability, and reliability make them the go-to choice for demanding industrial and laboratory applications.

When paired with proper installation, maintenance, and compatible furnace components, SiC heating elements offer exceptional performance and long service life.

If you’re looking for reliable SiC heating elements suppliers or custom solutions like silicon carbide heating rods or SiC crucibles, M-Kube Enterprise provides high-quality products trusted by industries worldwide.