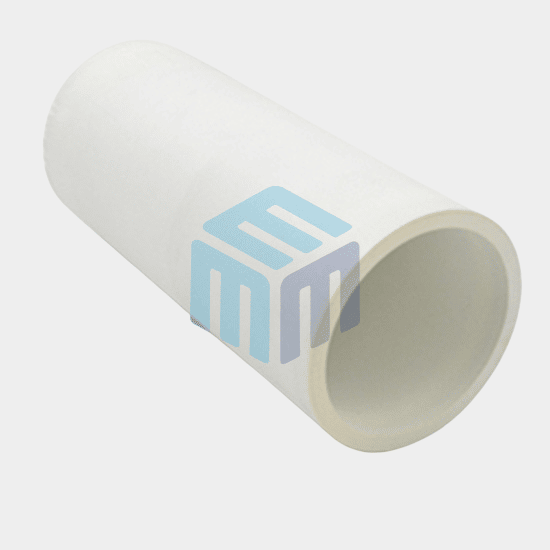

The benefits of using Boron Nitride tubes in High-Temperature applications

Boron nitride (BN) tubes are highly valued in high-temperature applications due to their unique combination of thermal, chemical, and electrical properties. Here are the key benefits of using boron nitride tubes in high-temperature applications:

- Exceptional Thermal Stability

- High-Temperature Resistance: Boron nitride tubes can withstand temperatures up to 2,000°C in inert

- or vacuum atmospheres, making them suitable for extremely high-temperature processes. They maintain their structural integrity at temperatures where many other materials would degrade.

- Thermal Conductivity: BN has a relatively high thermal conductivity, which allows for efficient heat dissipation. This is particularly beneficial in applications where precise temperature control is required.

- Excellent Thermal Shock Resistance

- Low Thermal Expansion: Boron nitride has a very low coefficient of thermal expansion, which contributes to its excellent thermal shock resistance. This means BN tubes can endure rapid temperature changes without cracking or deforming, making them ideal for applications involving extreme temperature cycling.

- Chemical Inertness

- Chemical Resistance: BN is chemically inert and resistant to most chemicals, including acids, alkalis, and molten metals. This makes BN tubes ideal for use in corrosive environments and processes where contamination must be minimized.

- Non-Wettability: Boron nitride is non-wettable by most molten metals and glasses, which is advantageous in applications like metal casting and glass processing where material purity is critical.

- Electrical Insulation

- Excellent Electrical Insulator: BN is an outstanding electrical insulator, even at high temperatures. BN tubes can be used in high-temperature electrical insulation applications, protecting components from electrical interference while withstanding the heat.

- High Machinability

- Ease of Machining: Despite its hardness, BN can be easily machined into complex shapes and precise dimensions without compromising its structural integrity. This makes BN tubes versatile for custom and specialized high-temperature applications.

- Customization: The ability to machine BN into intricate shapes allows for the creation of custom components tailored to specific high-temperature needs, such as complex furnace components or specialized electrical insulators.

- Lubricating Properties

- Self-Lubricating: BN has natural lubricating properties, reducing friction and wear in high-temperature environments. This self-lubricating ability makes BN tubes ideal for applications where moving parts are exposed to extreme heat, such as in sliding bearings or high-temperature seals.

- Low Density

- Lightweight Material: BN has a relatively low density compared to other high-temperature materials like alumina or zirconia, making it easier to handle and install. The lightweight nature of BN tubes can be particularly beneficial in applications where reducing the overall weight of components is a priority.

- High Purity

- Contamination-Free: High-purity BN tubes are often used in environments where contamination must be avoided, such as in semiconductor processing, where even trace impurities can affect the quality of the final product. BN’s chemical inertness and purity ensure that it does not introduce contaminants into sensitive processes.

- Compatibility with Various Atmospheres

- Inert and Reducing Atmospheres: BN tubes perform well in inert and reducing atmospheres, making them suitable for applications in furnaces, reactors, and other high-temperature environments where specific atmospheric conditions must be maintained.

- Vacuum Stability: BN remains stable and retains its properties in vacuum environments, which is crucial for processes like chemical vapor deposition (CVD) or high-vacuum furnaces.

- Durability and Longevity

- Resistance to Wear and Erosion: BN’s hardness and durability make it resistant to wear and erosion, ensuring a long service life even in harsh, abrasive environments. This contributes to the reliability and cost-effectiveness of BN tubes in high-temperature applications.

Applications of Boron Nitride Tubes in High-Temperature Environments

- Furnace Components: BN tubes are used as liners, crucibles, and protective sheaths in high-temperature furnaces due to their excellent thermal stability and resistance to chemical attack.

- Metal Processing: BN’s non-wettability by molten metals makes it ideal for use in metal casting, sintering, and other processes involving high-temperature metal handling.

- Semiconductor Manufacturing: BN tubes are used in the production of semiconductors where high-purity materials are required to prevent contamination during high-temperature processes.

- Electrical Insulation: BN tubes provide insulation for electrical components exposed to high temperatures, such as in heating elements or high-power electrical systems.

- Aerospace and Defense: In aerospace applications, BN tubes are used in high-temperature environments, such as in thermal protection systems, due to their light weight and high thermal resistance.

Summary

Boron nitride tubes offer numerous benefits for high-temperature applications, including exceptional thermal stability, chemical inertness, and excellent electrical insulation. Their ability to withstand extreme temperatures, resist chemical attacks, and provide effective thermal and electrical insulation makes them a versatile and reliable choice for a wide range of demanding environments. Whether used in furnaces, semiconductor manufacturing, or aerospace applications, BN tubes deliver long-lasting performance and help ensure the success of high-temperature processes.

M-Kube Enterprise is an Indian company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.