In high-temperature industrial applications, selecting the right material for furnace tubes, thermocouple protection, or chemical processing is critical. Among the most commonly used materials are Alumina Tubes (Al₂O₃), Quartz Tubes (SiO₂), and Silicon Carbide Tubes (SiC). Each of these materials brings unique advantages and limitations depending on the environment, temperature, and chemical exposure.

In this blog post, we’ll break down the key differences between Alumina tubes, Quartz tubes, and Silicon Carbide tubes to help you make an informed choice.

Temperature Resistance

-

Alumina Tubes:

- Withstand temperatures up to 1800°C or more, particularly when made from high-purity alumina (99.7% or higher).

- Alumina Tubes Suppliers offer products suitable for extreme high-temperature environments, such as furnaces and kilns.

-

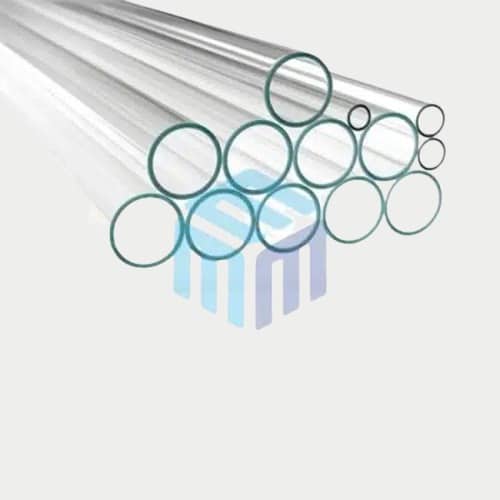

Quartz Tubes:

- Can withstand temperatures up to 1100°C.

- Suitable for moderate temperature applications but not ideal for extremely high temperatures.

-

Silicon Carbide Tubes:

- Have the highest temperature resistance of the three, handling temperatures up to 1600–2400°C depending on the grade.

- Ideal for applications involving extremely high heat and harsh environments, such as high-temperature furnaces or combustion chambers.

Mechanical Strength

-

Alumina Tubes:

- Excellent mechanical strength and durability, making them resistant to wear and stress at high temperatures.

- Can withstand heavy mechanical and thermal loads.

-

Quartz Tubes:

- Fragile compared to alumina and silicon carbide. Quartz is more prone to breaking under mechanical stress or impact, making it less durable.

-

Silicon Carbide Tubes:

- Superior mechanical strength and hardness, making them highly resistant to wear, abrasion, and thermal stress.

- Often preferred in environments with high mechanical loads.

Thermal Shock Resistance

-

Alumina Tubes:

- Good thermal shock resistance, but not as high as quartz. Rapid heating and cooling can cause cracking if not managed carefully.

-

Quartz Tubes:

- Excellent thermal shock resistance. Quartz can withstand sudden changes in temperature without cracking, making it useful in applications where rapid heating or cooling occurs.

-

Silicon Carbide Tubes:

- Moderate thermal shock resistance, better than alumina but not as good as quartz. Silicon carbide is tough, but extreme temperature fluctuations can still pose a challenge.

Chemical Resistance

-

Alumina Tubes:

- Highly resistant to chemical attack, especially from most acids and bases. Ideal for processes involving reactive chemicals at high temperatures.

-

Quartz Tubes:

- High resistance to chemical corrosion, particularly in oxidizing environments. However, it can be attacked by strong alkaline substances at high temperatures.

-

Silicon Carbide Tubes:

- Extremely resistant to chemical corrosion from a wide range of chemicals, including strong acids and alkalis. This makes it suitable for highly corrosive environments.

Electrical Insulation

-

Alumina Tubes:

- Excellent electrical insulator at high temperatures, making it ideal for applications where electrical insulation is crucial (e.g., thermocouple protection).

-

Quartz Tubes:

- Also a good electrical insulator, although alumina is generally preferred when higher thermal stability and electrical insulation are needed.

-

Silicon Carbide Tubes:

- Not a good insulator, as silicon carbide has some electrical conductivity, especially at high temperatures. It’s more suitable for applications where electrical conductivity is not a concern.

Cost

-

Alumina Tubes:

- Typically, mid-range in terms of cost. They offer a balance between performance and price, particularly for high-temperature applications requiring strength and durability.

-

Quartz Tubes:

- Generally more affordable than alumina or silicon carbide, especially for moderate temperature applications. However, the fragility may lead to more frequent replacements.

-

Silicon Carbide Tubes:

- More expensive than both alumina and quartz due to their superior properties. However, their durability and high-temperature resistance can justify the cost in demanding applications.

Applications

-

Alumina Tubes:

- Used in furnaces, thermocouple protection, kiln furniture, high-temperature processing, powder processing, and scientific research.

- Preferred when both high-temperature resistance and mechanical strength are required.

-

Quartz Tubes:

- Used in optics, semiconductor processing, light sources, and moderate temperature applications where thermal shock resistance is critical.

- Suitable for applications with rapid heating/cooling cycles but moderate temperature limits.

-

Silicon Carbide Tubes:

- Used in high-temperature furnaces, combustion systems, heat exchangers, and abrasive environments.

- Ideal for extreme temperature applications and environments with high mechanical or chemical stress.

Durability and Longevity

-

Alumina Tubes:

- High durability, especially in high-temperature or chemically aggressive environments, leading to longer life spans compared to quartz.

-

Quartz Tubes:

- Less durable due to their fragility, leading to shorter lifespans in environments with mechanical or thermal stress.

-

Silicon Carbide Tubes:

- Highly durable, with excellent resistance to wear and tear, especially in abrasive or chemically corrosive environments.

Read More : https://mkubeenterprise.co.in/properties-and-applications-of-quartz-tubes/

Summary of Key Differences: Alumina Tubes, Quartz and Silicon Carbide Tube

Alumina tubes offer a strong balance of high-temperature resistance, mechanical strength, and chemical stability, making them ideal for industrial furnaces and thermocouple protection. Quartz tubes are best suited for moderate temperatures with excellent thermal shock resistance, commonly used in semiconductor and lighting applications. Silicon carbide tubes excel in extreme environments, offering superior strength, wear resistance, and chemical durability for the most demanding industrial conditions.

| Property | Alumina Tubes | Quartz Tubes | Silicon Carbide Tubes |

| Max Temperature | Up to 1800°C | Up to 1100°C | Up to 2400°C |

| Mechanical Strength | Excellent | Fragile | Superior |

| Thermal Shock Resistance | Good | Excellent | Moderate |

| Chemical Resistance | High | High (except strong alkalis) | Excellent |

| Electrical Insulation | Excellent | Good | Poor |

| Cost | Mid-range | Affordable | Expensive |

| Applications | High-temp furnaces, sensors | Optics, semiconductors | High-temp furnaces, heat exchangers |

Conclusion:

Alumina tubes are the best choice when a balance of high-temperature resistance, mechanical strength, and chemical inertness is required, making them ideal for applications like industrial furnaces and thermocouple protection. Quartz tubes are well-suited for moderate-temperature environments where thermal shock resistance is essential, such as in semiconductor processing, lighting, and especially in quartz tube furnace setups, which are widely used in research and industrial labs, including across India. For the most extreme conditions involving very high temperatures, heavy wear, and chemical corrosion, silicon carbide tubes stand out as the most durable and high-performance option for demanding industrial environments.