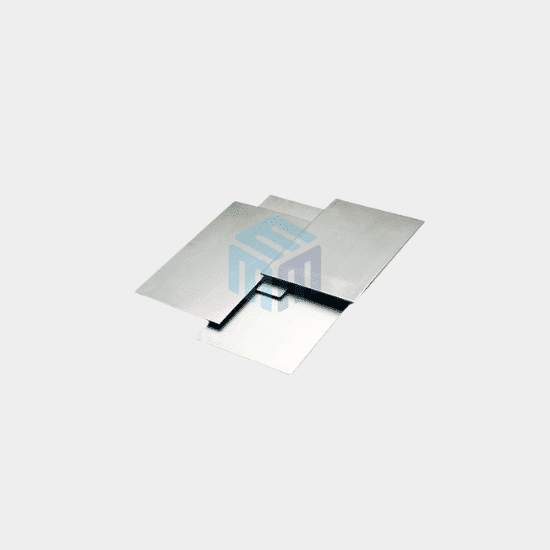

Molybdenum, a refractory metal known for its exceptional strength and resilience, has become an essential material across various industries. Available in a variety of forms, molybdenum sheets and plates stand out for their unique combination of mechanical, thermal, and chemical properties. In this blog, we explore the key characteristics and benefits that make molybdenum sheets and plates a go-to choice for demanding applications.

Key Properties of Molybdenum Sheets & Plates

Key Properties of Molybdenum Sheets & Plates

- High Melting Point Molybdenum boasts a melting point of 2622°C, making it ideal for applications involving extreme heat, such as aerospace components, high-temperature furnaces, and glass manufacturing.

- Excellent Thermal and Electrical Conductivity Its outstanding thermal conductivity ensures even heat distribution, while its electrical conductivity makes it suitable for electronic and semiconductor industries.

- Superior Strength and Toughness Molybdenum maintains structural integrity under high stress and temperature, offering exceptional durability and resistance to deformation.

- Corrosion Resistance Especially in non-oxidizing environments, molybdenum sheets and plates are resistant to corrosion, acids, and alkalis, increasing their lifespan and reducing maintenance costs.

- Low Thermal Expansion With a low coefficient of thermal expansion, molybdenum provides dimensional stability in applications that experience rapid or extreme temperature changes.

- Good Machinability Despite its hardness, molybdenum can be machined and fabricated using standard techniques, enabling versatility in design and engineering.

Advantages of Using Molybdenum Sheets & Plates

- High-Temperature Performance

Molybdenum sheets and plates can operate efficiently in extreme environments, making them indispensable in industries such as aerospace, defense, and energy. - Reliability in Electronics

Thanks to its conductivity and stability, molybdenum is a key material in the production of thin-film transistors, LCD panels, and semiconductors. - Improved Equipment Longevity

Its resistance to wear, oxidation, and chemical attack extends the service life of components and equipment, translating into long-term cost savings. - Lightweight Alternative

Compared to other refractory metals, molybdenum offers high strength-to-weight ratio, which is beneficial in weight-sensitive applications. - Eco-Friendly and Recyclable

Molybdenum is a sustainable choice as it is 100% recyclable without loss of properties, aligning with modern environmental standards.

Applications Across Industries

Molybdenum sheets and plates are widely used in:

- High-temperature furnace construction

- Electronics and semiconductor devices

- Aerospace and defense components

- Nuclear energy systems

- Metal processing equipment

- Medical imaging and diagnostic devices

Conclusion

Whether you’re designing high-performance equipment or manufacturing components that must withstand extreme conditions, molybdenum sheets and plates from reliable unmatched reliability, efficiency, and value. Their unique combination of properties makes them an ideal choice for a broad range of industrial and technological applications, and working with trusted molybdenum sheet suppliers ensures consistent quality and performance.

Looking to source high-quality molybdenum products in Australia? M-kube is your trusted partner for advanced material solutions. Reach out to our team today to learn more.