Graphite Customization Applications

Inquiry NowProduct Description

Graphite is a versatile material known for its excellent thermal and electrical conductivity, chemical inertness, and lubricating properties. Customization in graphite applications is often essential to meet specific requirements for various industries. Here are some common applications and ways in which graphite can be customized:

- Electrodes and Conductive Components: Customized graphite electrodes are used in the steel and aluminum industries for smelting and refining processes. Customization may include specific sizes, shapes, and thermal properties to suit different furnaces and processes.

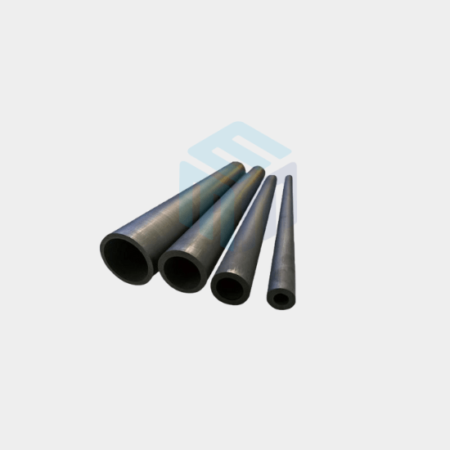

- Heat Exchangers: Graphite heat exchangers are used in chemical and industrial applications. Customization can involve designing heat exchangers with specific dimensions, surface areas, and thermal performance characteristics.

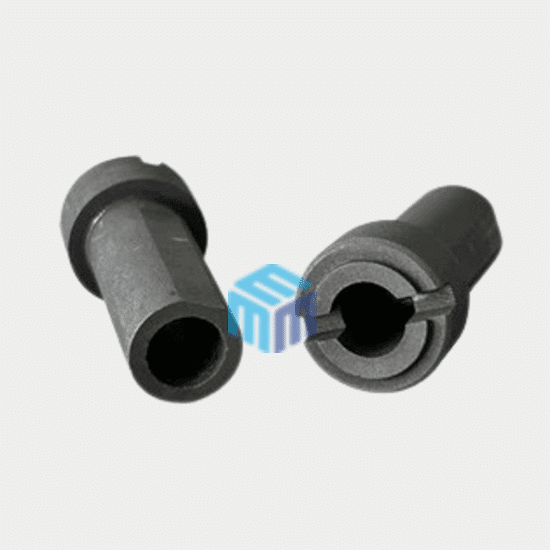

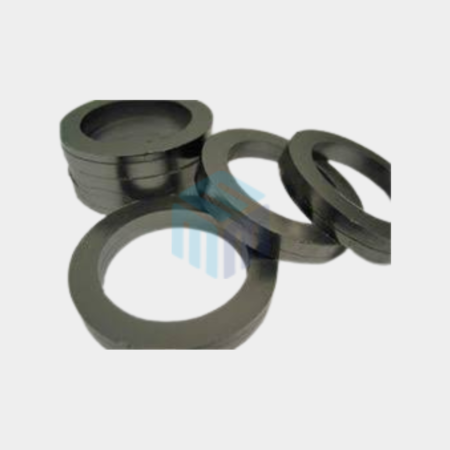

- Sealing and Gasket Materials: Customized graphite gaskets and seals are used in high-temperature and high-pressure applications, such as in petrochemical and nuclear industries. Customization may involve the design of gaskets with specific shapes and properties.

- Lubricants: Graphite is used as a solid lubricant in various industries. Customization can involve the formulation of lubricating compounds with specific graphite particle sizes and additives for different applications.

- Foundry Crucibles and Molds: Customized graphite crucibles and molds are used in the casting of metals and alloys. Customization may include designing crucibles of specific sizes and shapes to accommodate different casting requirements.

- Electrical Components: Customized graphite components, such as brushes and commutators, are used in electrical machinery and equipment. The customization can involve specific geometries and electrical conductivity properties.

- Semiconductor Equipment: Graphite is used in semiconductor manufacturing equipment, including wafer carriers and susceptors. Customization may involve the design of components with precise dimensions and purity levels to meet the requirements of different semiconductor processes.

- Graphite Insulation: Customized graphite insulation materials are used in high-temperature applications. The customization can include insulation thickness, composition, and thermal conductivity properties.

- EDM Electrodes: Customized graphite electrodes are used in electrical discharge machining (EDM) for precision machining of conductive materials. Customization can involve electrode shapes, sizes, and surface finishes.

- Carbon and Graphite Composites: Customized carbon and graphite composites are used in various applications, such as aerospace components, sporting goods, and industrial equipment. Customization may involve specific composite materials and manufacturing processes.

- Analytical Instruments: Graphite is used in analytical instruments, such as atomic absorption spectrometers and atomic emission spectrometers, as a sample introduction component. Customization can include specific component geometries and materials to enhance analytical accuracy.

To achieve customization in graphite applications, it is important to work with manufacturers or suppliers specializing in precision graphite production and processing. These experts can assist in the design, engineering, and production of graphite components and materials to meet specific material properties, geometrical dimensions, surface finishes, and functional requirements, ensuring that the final product aligns with the intended application. Customization is crucial to optimize the performance and functionality of graphite in various industrial and technological sectors.

We are an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Indonesia, Dubai, Philippines and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at marketing@mkubeenterprise.co.in or call us at +91-9898892994 to discuss your projects.