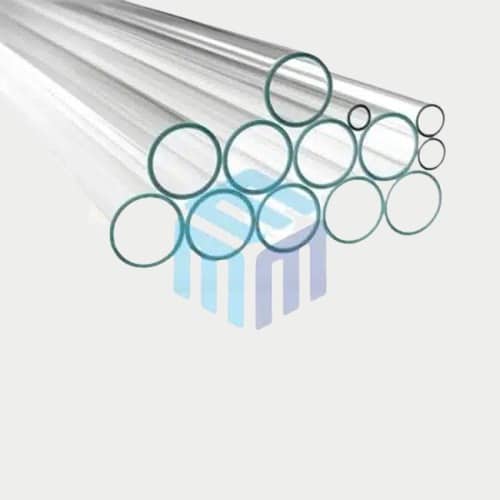

Quartz tubes play a critical role in various high-temperature, high-purity, and precision applications. Their unique thermal and optical properties make them indispensable in laboratory, industrial, and scientific settings. Whether you’re working in materials science, electronics, or chemical processing, understanding the properties and advantages of quartz tubes helps in selecting the right component for your system.

What Are Quartz Tubes?

Quartz tubes are cylindrical components made from fused silica (SiO₂) — a material known for its purity, thermal stability, and optical clarity. Unlike standard glass, quartz has a much higher melting point and superior resistance to thermal shock.

Quartz tube meaning refers to its form and function: a transparent, heat-resistant tube used in controlled environments, typically for heating or chemical interaction.

Importance of Quartz Tubes in Industrial and Scientific Applications

Quartz tubes are widely used in environments where precision, temperature resistance, and chemical purity are critical. A quartz tube furnace, for instance, relies on quartz tubes to safely contain and heat samples at temperatures exceeding 1000°C without contamination.

Common applications include:

- Semiconductor fabrication

- Chemical vapor deposition (CVD)

- Laboratory heating

- UV disinfection systems

- High-temperature reaction vessels

In India, the demand for quartz tube furnaces and quartz furnace tubes has grown significantly, especially across research labs and industrial R&D centers.

Properties of Quartz Tubes

-

Thermal Properties

- High Thermal Stability: They can withstand very high temperatures, up to 1,050°C for prolonged periods. They have a melting point of about 1,710°C, making them suitable for high-temperature processes. Quartz tube furnaces utilize these tubes to perform tasks like annealing, sintering, and chemical vapor deposition (CVD), as they provide precise control of high temperatures and uniform heating, essential for various industrial and laboratory applications.

- Low Thermal Expansion: Quartz has an extremely low coefficient of thermal expansion, meaning it doesn’t expand or contract significantly with temperature changes. This property provides excellent thermal shock resistance, allowing quartz tubes to withstand rapid heating and cooling without cracking.

- Heat Resistance: Quartz tubes can resist thermal cycling, making them ideal for applications where consistent and repeated exposure to high temperatures is required.

-

Optical Properties

- High Transparency: Quartz tubes are highly transparent to a broad spectrum of light, including ultraviolet (UV) and visible light. This makes them suitable for optical and photonics applications.

- UV Transmission: They have excellent UV transmission, which is crucial for applications such as UV sterilization and photolithography.

- Optical Clarity: The optical clarity of quartz tubes makes them suitable for use in scientific instruments, optical fibers, and other applications requiring precise light transmission.

-

Chemical Properties

- Chemical Inertness: Quartz is chemically inert and highly resistant to most acids, bases, and solvents. It does not react with most substances, making it ideal for use in corrosive environments.

- Purity: They are available in very high purity levels, which is essential for applications in semiconductor manufacturing, where contamination must be minimized.

-

Electrical Properties

- Electrical Insulation: Quartz is an excellent electrical insulator, even at high temperatures. This property makes quartz tubes suitable for use in high-temperature electrical insulation applications.

-

Mechanical Properties

- Durability: They are mechanically strong, though they can be brittle. Their resistance to thermal shock contributes to their durability in high-temperature applications.

- Hardness: Quartz is relatively hard (7 on the Mohs scale), providing good scratch resistance and maintaining its structural integrity under mechanical stress.

Applications of Quartz Tubes

-

Laboratory and Scientific Use

- High-Temperature Furnaces: They are used as reaction vessels or protective enclosures in high-temperature furnaces due to their ability to withstand extreme heat and thermal cycling.

- Chemical Reactions: Their chemical inertness makes them ideal for conducting reactions involving aggressive chemicals or for processes requiring a contaminant-free environment.

- Spectroscopy and Optical Instruments: The optical clarity and UV transparency of quartz tubes are essential in spectroscopy, where they are used as sample containers or light guides.

-

Semiconductor Manufacturing

- Diffusion and Oxidation Processes: They are widely used in semiconductor manufacturing, particularly in diffusion and oxidation furnaces, where their high purity and thermal stability are critical.

- Wafer Processing: The tubes serve as enclosures for semiconductor wafers during various high-temperature processes, ensuring minimal contamination and consistent thermal distribution.

-

UV Sterilization and Disinfection

- Germicidal Lamps: Quartz tubes are used in UV germicidal lamps, where their high UV transmission allows for effective disinfection of air, water, and surfaces in medical, industrial, and residential settings.

- Water Purification Systems: They are used in UV water purification systems, where they protect the UV lamps and ensure efficient UV light transmission.

-

Industrial Applications

- Heating Elements: They are used as protective sheaths for heating elements in industrial furnaces and heaters, particularly in processes that require uniform and controlled heating.

- Glass Manufacturing: In glass production, quartz tubes can be used to house high-intensity lamps or as part of the equipment used in glass processing.

-

Optical and Photonic Devices

- Optical Fibers: They are used in the production of optical fibers, where their transparency and purity ensure efficient light transmission with minimal loss.

- Laser Systems: They are also used in laser systems as beam guides or enclosures, benefiting from quartz’s high optical clarity and resistance to heat.

-

Environmental Monitoring and Sensing

- Gas Analyzers: They are employed in environmental monitoring equipment, such as gas analyzers, where their chemical resistance and transparency are crucial for accurate readings.

- Aerosol Research: In aerosol research, quartz tubes are used to collect and analyze particulate samples, leveraging their inertness and thermal stability.

Also Read: Alumina Tubes vs. Quartz and Silicon Carbide Tube

Summary

Quartz tubes are a versatile material with a wide range of applications due to their high thermal stability, optical clarity, chemical resistance, and electrical insulation properties. Often referred to as Quartz Glass Tubing, these components are essential in industries such as semiconductor manufacturing, laboratory research, UV sterilization, industrial heating, and optical devices. With the growing demand for high-performance materials, Quartz Tube India suppliers are increasingly providing customized solutions for both domestic and international markets. Choosing the right quartz tube for your application ensures reliable performance in demanding environments where high temperatures, purity, and chemical inertness are required.

M-Kube Enterprise is an Indian company catering customized laboratory products, laboratory consumables, and laboratory solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, Dubai, the Philippines, Indonesia, and Vietnam.