Magnesia crucibles

Inquiry NowProduct Description

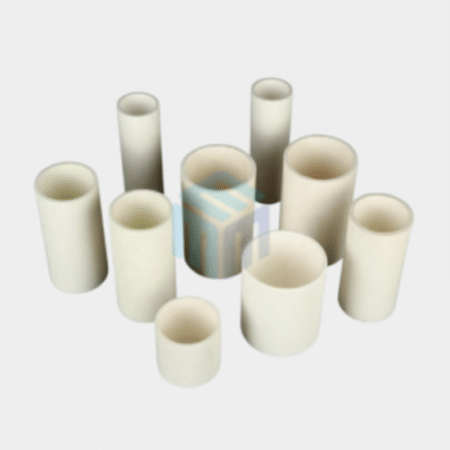

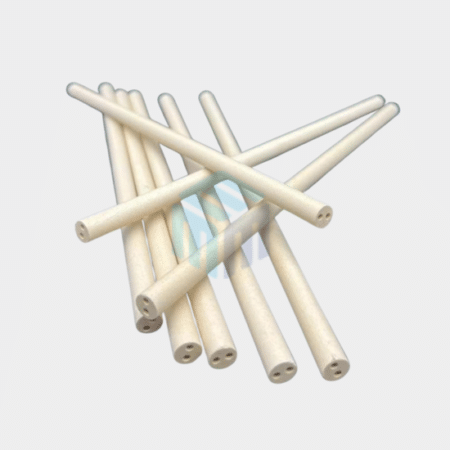

Magnesia Crucibles – High-Temperature MgO Crucibles for Demanding Indian Applications

M-Kube Enterprise is a leading supplier of magnesia crucibles in India, delivering high-purity magnesium oxide (MgO) crucibles engineered for use in extreme thermal, chemical, and alkaline environments. With a melting point above 2800°C and superior resistance to corrosive agents, our MgO crucibles are ideal for applications where alumina or silica fall short.

Whether you operate a research lab, metallurgy plant, ceramics unit, or analytical facility, M-Kube provides reliable solutions with fast delivery and technical support across India.

Standard and Custom MgO Crucibles for Indian Industries

At M-Kube Enterprise, we offer a wide range of standard and custom magnesia crucibles to support your industrial or research-grade processes. Each crucible is manufactured to meet stringent quality standards for strength, purity, and thermal performance.

Customization Options Include:

- Cylindrical, conical, or tapered crucible shapes

- Custom diameters, heights, and wall thicknesses

- Closed or open-bottom configurations

- Smooth or rough interior surface finish

- Bottom hole drilling and prototype development support

Our magnesia crucibles are capable of withstanding:

- Up to 2000°C in air

- 1700°C in reducing atmospheres

- 1600°C in vacuum environments

These characteristics make them perfect for aggressive, high-temperature processes often required in India’s mining, metallurgy, and materials science sectors.

Key Features of M-Kube’s Magnesia Crucibles

Our MgO crucibles are crafted with performance and reliability in mind:

- Extreme temperature resistance for thermal processing

- Excellent chemical stability in basic and alkaline environments

- Low reactivity with metals and other ceramics

- High thermal conductivity and shock resistance

- Good electrical insulation at elevated temperatures

- Dense, low-porosity construction for long-term durability

These features make our magnesia crucibles an optimal choice for heat-intensive and chemically reactive applications.

Applications of Magnesia Crucibles in Indian Industries

Magnesia crucibles are widely used across various industries and research sectors in India, including:

- Fusion flux analysis in mining and geology labs

- Sample preparation in metallurgical and material testing labs

- Processing of rare earths and superalloys

- Thermal treatment of reactive or alkaline metals

- Sintering, ashing, and high-temperature firing in ceramics

- R&D experiments in extreme environments

Looking for alternatives? You can also explore our alumina crucibles, quartz crucibles, or boron nitride crucibles for different chemical compatibility requirements.

Why Choose M-Kube Enterprise as Your Magnesia Crucible Supplier in India?

M-Kube Enterprise stands out as a trusted magnesia crucible supplier in India due to:

- High-purity MgO raw materials sourced for Indian and global standards

- Extensive customization and volume capabilities

- Fast response and expert consultation from our technical team

- Consistent quality control and dimensional accuracy

- Reliable delivery and support across all Indian regions

We’re proud to serve India’s top laboratories, research institutes, and industrial processing facilities with performance-driven ceramic solutions.

✅ Trusted Magnesia Crucible Supplier in India – Contact M-Kube Enterprise

M-Kube Enterprise offers precision-engineered MgO crucibles designed for use in fusion analysis, metallurgical testing, high-temperature chemical processing, and advanced R&D. Our team is equipped to handle both custom and bulk requirements with speed and technical accuracy.

✅ Multiple standard sizes and custom shapes

✅ Superior performance under harsh thermal and chemical conditions

✅ Ideal for mining, materials science, and ceramic industries

📞 Call us at +91 9898892994

📧 Email us at marketing@mkubeenterprise.co.in

to request a quote or speak with our ceramic materials experts today!

Product FAQ's

Magnesia crucibles are ideal for high-temperature applications, especially in metallurgy, ceramics, and chemical labs. They are excellent for melting and firing materials that react with alumina or silica.

Magnesia crucibles can typically withstand temperatures up to 2,000°C, making them suitable for ultra-high-temperature furnaces and aggressive chemical environments.

Yes, depending on the process and conditions, magnesia crucibles can be reused multiple times. However, their lifespan depends on temperature cycles and chemical exposure.

Yes, reputable magnesia crucible suppliers like M-Kube offer customized crucibles in various shapes, sizes, and purities to meet specific laboratory or industrial needs.

Standard forms include cylindrical, conical, and flat-bottomed crucibles, though magnesia crucible suppliers can provide custom geometries based on your application.