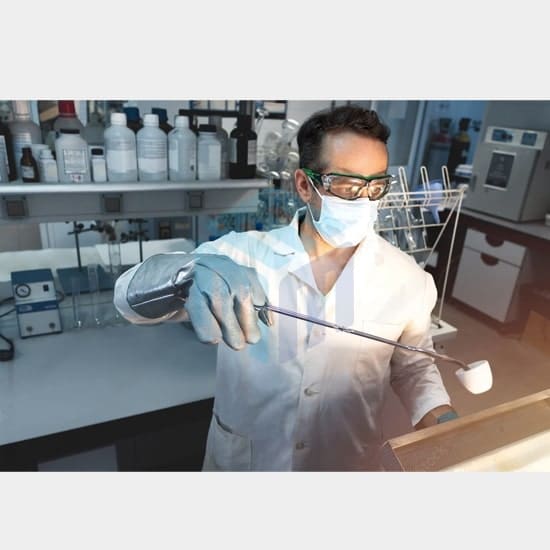

Selecting the appropriate crucible material for your research involves several key considerations to ensure compatibility with your experimental needs. Here are the crucial factors to help you choose the right crucible material:

- Temperature Range: Select a crucible material that can endure the required temperatures without melting, deforming, or reacting with the sample or environment.

- Chemical Compatibility: Choose a crucible material that is chemically inert or resistant to the substances used in your research to avoid reactions, dissolution, or contamination.

- Thermal Conductivity: Consider whether your experiment requires high or low thermal conductivity for efficient heat transfer or temperature maintenance, respectively.

- Mechanical Strength and Durability: Ensure the chosen crucible material can withstand mechanical forces without fracturing, cracking, or deforming, based on factors like sample weight and stirring requirements.

- Sample Reactivity: Opt for a crucible material resistant to reactive or corrosive samples to prevent contamination or damage to the crucible.

- Sample Visibility: If sample observation is necessary, consider the transparency or opacity of the crucible material to visible light or specific wavelengths.

- Availability and Cost: Factor in the availability and cost of crucible materials to choose one that meets your budget and accessibility needs.

- Experimental Constraints: Take into account any specific experimental requirements, such as compatibility with heating methods or dimensional constraints, when selecting the crucible material.

Common Crucible Materials

Here are some commonly used ceramic materials for crucibles in various research and industrial applications:

- Alumina (Aluminium Oxide): Widely used for its high-temperature stability, chemical inertness, and mechanical strength, alumina crucibles are suitable for various high-temperature and corrosive applications.

- Zirconia (Zirconium Dioxide): Known for exceptional thermal shock resistance and high-temperature stability, zirconia crucibles find applications in environments with molten metals and slags.

- Silicon Carbide: Highly refractory with excellent thermal conductivity, silicon carbide crucibles are commonly used in applications involving molten metals like aluminum and copper.

- Boron Nitride: Boron nitride crucibles exhibit high thermal conductivity and resistance to thermal shock, making them suitable for non-wetting properties with molten metals.

- Quartz (Silica): Transparent to visible light and thermally resistant, quartz crucibles are often used in applications requiring sample visibility or UV transparency.

- Magnesia (Magnesium Oxide, MgO): Offering good thermal shock resistance, magnesia crucibles are suitable for high-temperature applications involving materials like magnesium.

- Mullite: Known for good thermal shock resistance and creep resistance at high temperatures, mullite crucibles are used in glass manufacturing and metal melting.

- Graphite: Preferred for high-temperature applications, graphite crucibles have excellent thermal conductivity and chemical resistance.

- Platinum: Highly resistant to corrosion, platinum crucibles are suitable for noble metal analysis and high-temperature reactions.

- Tungsten: With a high melting point and excellent resistance to thermal shock, tungsten crucibles are commonly used in extremely high-temperature applications.

- Porcelain: Suitable for general-purpose laboratory use, porcelain crucibles are chemically inert to most substances but may not withstand high temperatures or corrosive environments.

M-Kube is an Indian company catering products and solutions in India, Australia, the USA, New Zealand, Singapore, Malaysia, South Korea, and Vietnam. Our team of experts across different platforms can discuss and customize your requirements as per your needs.

Please reach out to us at [email protected] or call us at +91-9898892994 to discuss your projects.